The future of hydrogen technology is being created in Neu-Ulm. Dana Incorporated is building the largest production line for metallic bipolar plates in Europe at the REINZ-Dichtungs-GmbH site by 2023. At its peak, Dana will produce up to 16 million metallic bipolar plates per year.

With the transformation of the product portfolio in the direction of electromobility, Dana is creating the prerequisites for securing the Neu-Ulm location with over 1,300 employees.

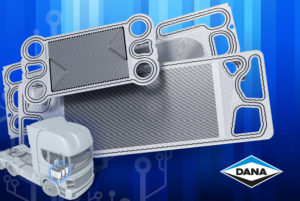

Metallic bipolar plates in stacks of up to several hundred plates form the core of fuel cell stacks. These stacks generate the energy for fuel cell electric drives.

Investment in the high double-digit million range

The current production capacity of the pilot plant is around 350,000 metallic bipolar plates per year. By investing in additional machines, the small-series line will be ramped up to about 800,000 plates per year by summer 2022. In parallel, a separate high-volume line for four million plates p.a. is being built, which will be further expanded after the start of production (SOP) in 2023.

In total, Dana Incorporated is investing a high double-digit million amount in the future of fuel cell technology at the Neu-Ulm site and is creating around 40 jobs in the e-mobility sector.

Orders from Bosch and PowerCell

With the expansion of the production of metallic bipolar plates, Dana Neu-Ulm/REINZ-Dichtungs-GmbH is systematically continuing its transformation process.

transformation process. The company is successfully exploiting unique technological features and competitive

competitive advantages from the world of the combustion engine to develop innovations for the electrification of mobility – from battery to fuel cell technology. Bosch and PowerCell have already placed orders for the production of over 100 million metallic bipolar plates in the coming years.

Mobility of the future

Fuel cell technology has the potential to change mobility in the long term. So far, however, this form of propulsion has not been able to gain widespread acceptance, not least because of the high cost of fuel cell stacks. The metallic bipolar plate from Dana should make a significant contribution to this and advance the commercialisation of the fuel cell. Currently, the highly integrated metallic bipolar plate from Neu-Ulm already reduces the total costs for fuel cell stacks by up to 10 percent.

About Dana Neu-Ulm/REINZ-Dichtungs-GmbH

As an international supplier to the automotive industry, REINZ-Dichtungs-GmbH specialises in the development and production of sealing technology and fuel cell components. As an original equipment manufacturer, the company works with all major automobile and engine manufacturers worldwide – from Smart to Bugatti. In addition, the VICTOR REINZ brand stands for the most comprehensive range of service parts for the aftermarket.

In addition to gaskets and shielding solutions for the automotive industry, REINZ-Dichtungs-GmbH also develops and produces special gasket concepts for industrial applications – from combined heat and power plants to breweries.

REINZ-Dichtungs-GmbH, with over 1,300 employees, has been part of Dana Incorporated since 1993. Founded in 1904 and headquartered in Maumee in the US state of Ohio, the company employs 40,000 people in 31 countries on six continents and generated a turnover of 8.9 billion US dollars in 2021. Dana is committed to sustainability and social responsibility, for which it was named one of “America’s Most Responsible Companies 2022” by Newsweek. The company has established a high-performance culture that focuses on valuing others, fostering innovation, responsible growth and shared success. This culture has earned Dana global recognition as a top employer.

For more information, visit www.dana.com.