A research team from the Universities of Ulm and Jena has succeeded in decisively advancing the development of solar-driven catalysts. Their optimised photocatalysts are more effective than conventional thermal catalysts and thus lay a foundation for the sustainable use of regenerative energies in the chemical industry. The advantage: no major investments are needed to convert process technology to sun-based methods.

Around 80 percent of all chemical products are manufactured with the help of catalytic processes. Catalysts accelerate chemical reactions or get them going in the first place by lowering the so-called activation energy. This task is often performed by thermal catalysts, whose use is linked to the consumption of fossil energy. But light from the sun can also be used effectively for catalytic processes. Proof of this has recently been provided by scientists at the Universities of Ulm

and Jena recently provided proof of this. They succeeded in optimising a sunlight-driven photocatalyst in such a way that it works faster and more efficiently than a conventional thermal catalyst. “This development opens the door to a sustainable solar future for the chemical industry,” says Professor Sven Rau, head of the Institute of Inorganic Chemistry I at Ulm University.

Together with his colleague Professor Benjamin Dietzek-Ivanšić from Jena, the chemist from Ulm has coordinated a study that impressively demonstrates the performance of photocatalysts. “We were able to show that the design of the catalyst plays a decisive role for the speed of the light reaction that takes place – but not for the thermal reaction,” explains

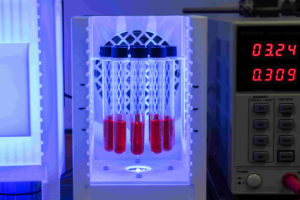

Dietzek-Ivanšić, who conducts research at the Institute of Physical Chemistry at the University of Jena and heads the Functional Interfaces research department at the Leibniz Institute for Photonic Technologies. The photocatalyst under investigation consists of three chemically active components: a centre for absorbing light energy, a bridge and a catalysis centre. Surprisingly, the experiments showed that the structure of the bridge in particular has a decisive influence on the efficiency of the catalyst,” confirm the researchers.

catalyst,” confirm the first authors of the study, Dr. Linda Zedler (University of Jena) and Pascal Wintergerst (University of Ulm). With the help of chemical syntheses, catalytic investigations and ultrafast spectroscopy, the research team was able to elucidate the processes taking place in detail.

The study published in Nature Communications shows that such solar-driven photocatalysts are suitable for producing energy-rich, high-quality reaction products from low-energy starting materials. If conventional thermal catalysts are used, on the other hand, higher-energy starting materials are needed to enable comparable reactions.

Evidence from a biotechnologically significant example

The chemists provided proof of this for an application example with great biotechnological potential: the hydrogenation of nicotinamide, which produces an energy-rich molecule with extensive application possibilities. The organic compound nicotinamide is a central component of nicotinamide adenine dinucleotide (NAD+ or NADH). This coenzyme is involved in numerous redox reactions of the metabolism in living cells. For the researchers, the photocatalytically mediated hydrogenation of nicotinamide is visible proof that solar chemistry and biotechnological applications can be optimally coupled. With the construction plans for future solar-powered catalysts that the

The construction plans for future solar-driven catalysts, which the research team established in this study, also provide fundamental insights into how the energy of sunlight can be efficiently converted into chemical binding energy and stored as such. This process is central to the use of solar energy modelled on nature.

“Basically, however, the research project has just shown that catalytic processes can be put on a solar basis with the help of optimised photocatalysts – and with a gain in catalytic efficiency,” the researchers assure. Large investments in the chemical industry are not necessary for this. Material flows could be maintained, and the technological basis of chemical

technological basis of chemical process technology could be used without any problems. This would be a groundbreaking step for the chemical industry to become more sustainable and less dependent on fossil fuels.

The project was funded by the German Research Foundation (DFG) as part of the Transregional Collaborative Research Centre (SFB) 234 CataLight of the Universities of Ulm and Jena. The SFB was extended for another four years at the end of May and will be funded with 12 million euros. The goal of CataLight is to use sunlight for a climate-friendly energy supply, following the example of natural photosynthesis. Further funding comes from doctoral programmes of the German National Academic Foundation and the Chemical Industry Fund.